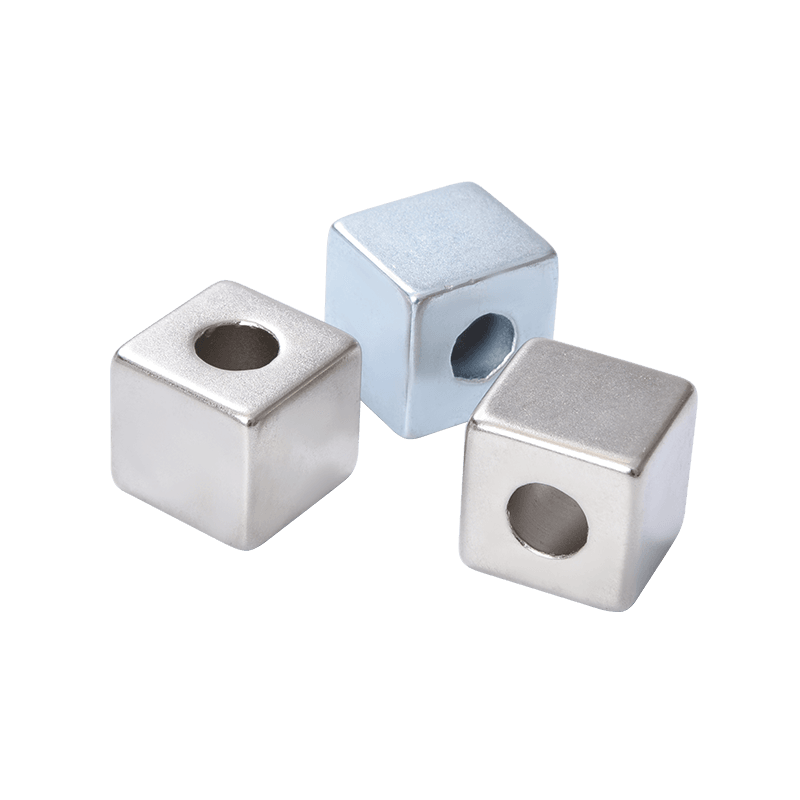

The corrosion-resistant coating of Square NdFeB Magnets generally effectively protects the magnets from damage in humid environments, but the protective effect is influenced by various factors.

Firstly, the type and quality of the corrosion-resistant coating play a crucial role in the protection. High-quality coatings have excellent water resistance and corrosion resistance, forming a strong barrier in humid environments to prevent direct contact between the magnet and moisture and oxygen in the air, effectively slowing down the oxidation and corrosion of the magnet.

Secondly, the quality and thickness of the coating also affect its protective effect. The coating needs to be evenly and completely covered on the surface of the magnet without defects such as missed coating, bubbling, or peeling. At the same time, the thickness of the coating needs to be moderate; too thin may not provide sufficient protection, while too thick may affect the magnetic performance of the magnet.

However, despite the certain protective effect of the corrosion-resistant coating, in extremely humid or long-term immersion environments, the coating may be damaged, leading to corrosion of the magnet. In addition, if the coating itself has quality issues or is improperly applied, it may also result in poor protection.

Therefore, when using Square NdFeB Magnets, besides choosing high-quality corrosion-resistant coatings, attention should also be paid to the following points:

1. Try to avoid prolonged exposure of the magnets to humid environments, especially in environments with high humidity or corrosive factors such as salt spray.

2. Regularly inspect and maintain the coating of the magnets, and repair any damage or peeling of the coating promptly.

3. For magnets that need to be used for a long time in humid environments, consider adopting higher-level protective measures such as using sealed packaging or installing desiccants.

In summary, the corrosion-resistant coating of Square NdFeB Magnets can effectively protect the magnets from damage in general conditions. However, under special circumstances, additional protective measures are still needed to ensure their stability and performance.

English

English русский

русский Español

Español