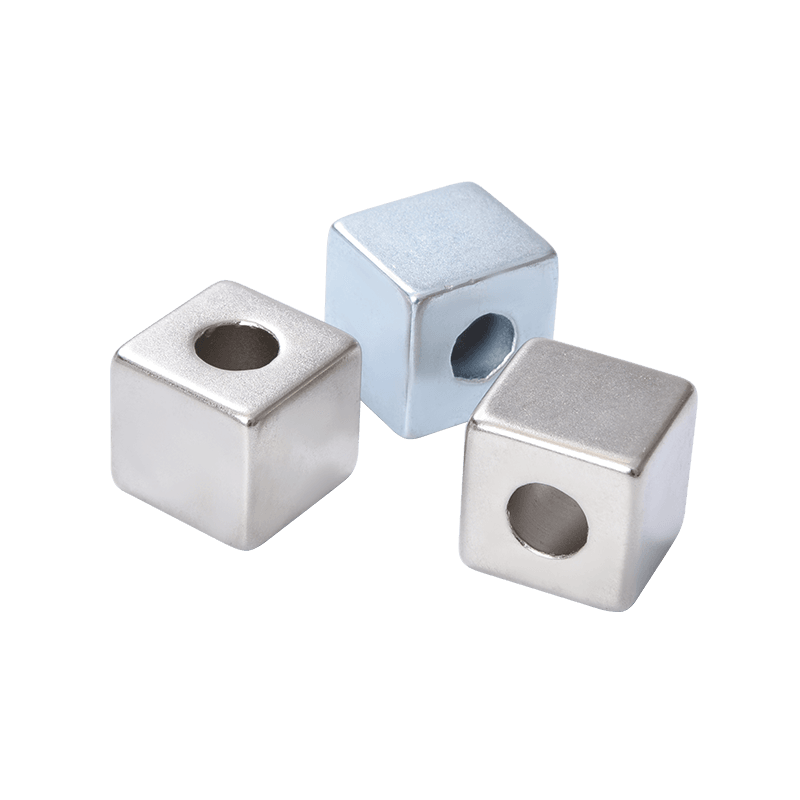

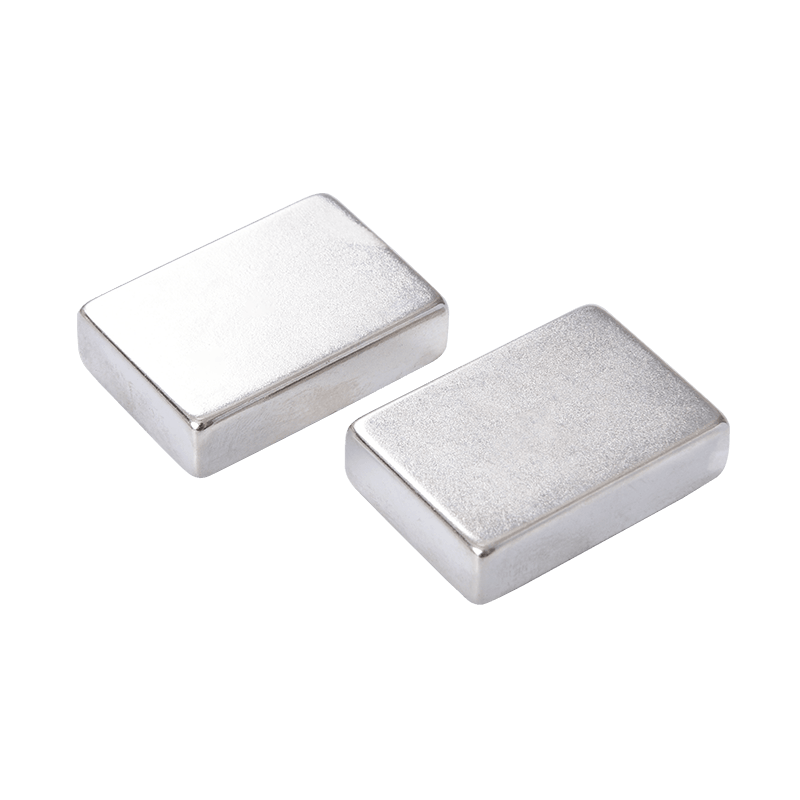

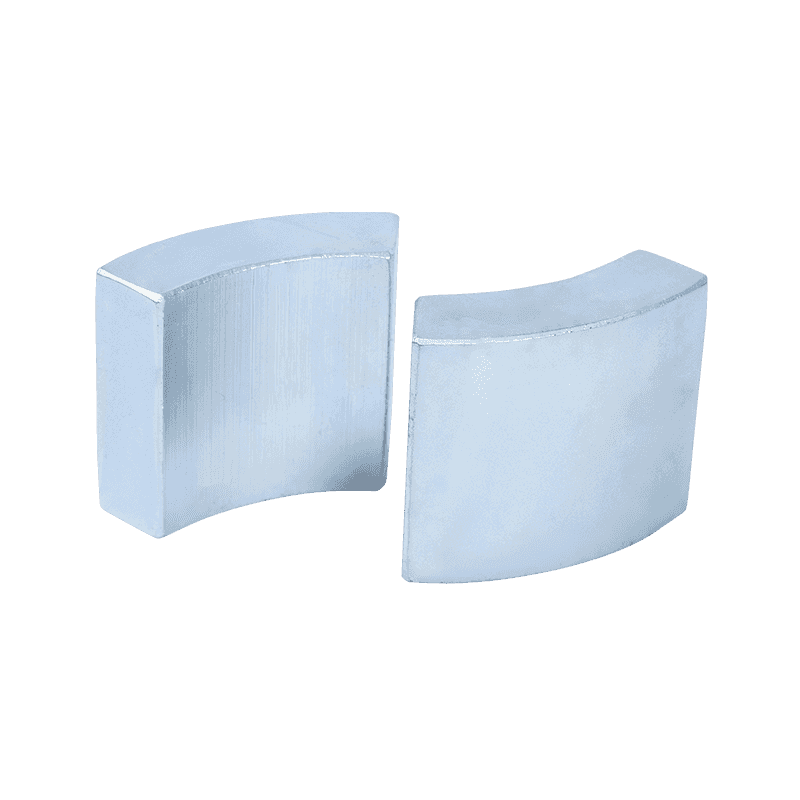

In many fields of modern industry and technology, Special Shaped NdFeB Magnet plays a critical role with its excellent magnetic performance. However, different working environments pose various challenges to its magnetic performance, and it also adapts cleverly with its unique design and processing methods.

In high-temperature working environments, such as the motor system of electric vehicles or the sensor devices near some industrial furnaces, the magnetic performance of ordinary NdFeB magnets will drop sharply due to the limitation of Curie temperature. However, Special Shaped NdFeB Magnet can improve its heat resistance through special alloy formula adjustment. For example, adding appropriate amounts of heavy rare earth elements such as dysprosium (Dy) and terbium (Tb), these elements can effectively inhibit the movement of magnetic domain walls at high temperatures, thereby maintaining the high coercivity of the magnet, ensuring that sufficient magnetic field strength can still be stably provided in high-temperature environments to ensure the normal operation of the equipment. At the same time, the use of advanced plating technology, such as nickel plating or multi-layer composite plating, can not only prevent the magnet from being oxidized and corroded at high temperatures, but also further reduce the loss of magnetic performance caused by high temperatures.

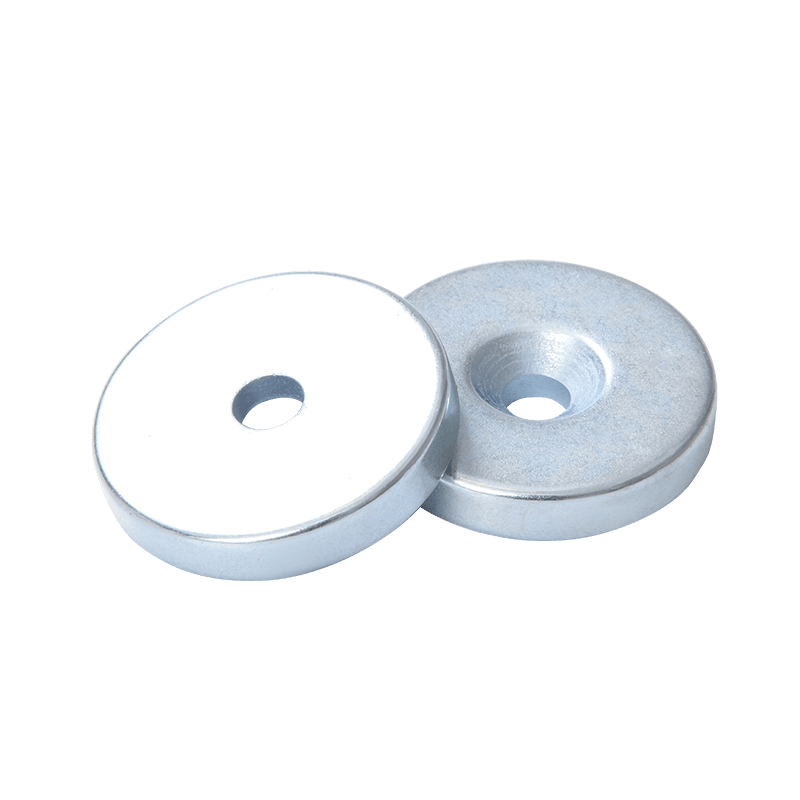

In humid or corrosive environments, such as magnetic components in marine equipment or magnetic sensors on chemical production lines, Special Shaped NdFeB Magnet relies on high-quality protective coatings to adapt. The epoxy resin coating can form a dense protective film to prevent moisture, salt and various chemical corrosive substances from contacting the magnet substrate. Even in a long-term high-humidity marine environment, this coating can effectively prevent the magnet from rusting and magnetic degradation, ensuring its reliable operation in marine monitoring equipment, underwater vehicles, etc., accurately sensing magnetic field changes, and providing accurate magnetic signal feedback for the operation of the equipment.

In working scenarios with strong vibration and impact, such as some electromechanical equipment in the aerospace field or high-speed industrial machinery, the special-shaped structural design of Special Shaped NdFeB Magnet highlights its advantages. Its special shape can better fit and fix with the surrounding structure, reducing displacement and looseness caused by vibration and impact. At the same time, bonding technology is used in the manufacturing process to bond the magnets with other high-strength, impact-resistant materials to form an integral structure, which enhances the mechanical stability of the magnets and ensures that the magnetic properties remain stable when subjected to strong external forces. It will not change suddenly due to deformation or displacement of the structure, thereby ensuring the normal operation of the entire system.

English

English русский

русский Español

Español