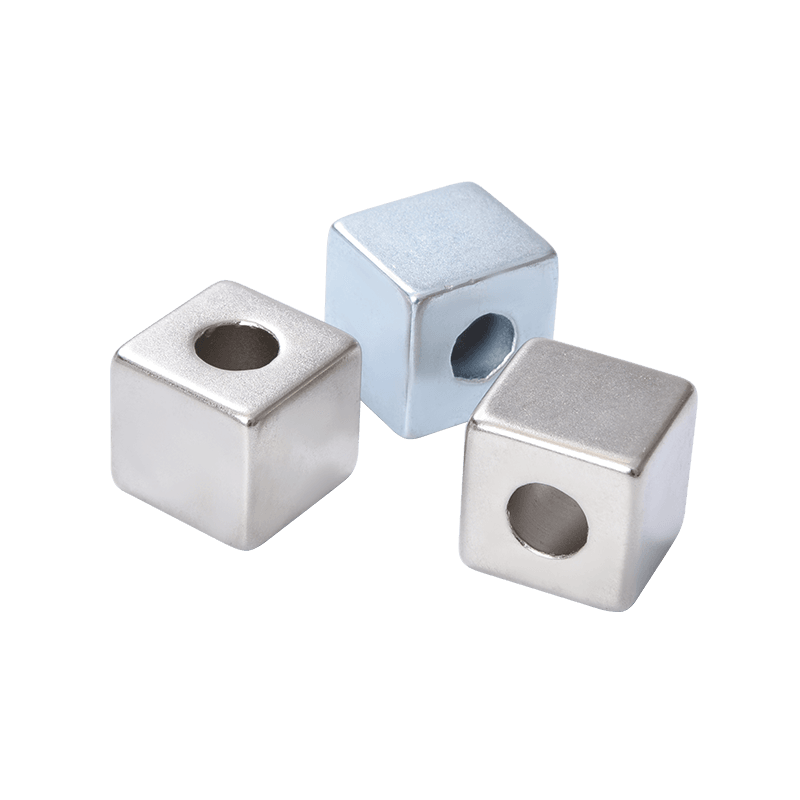

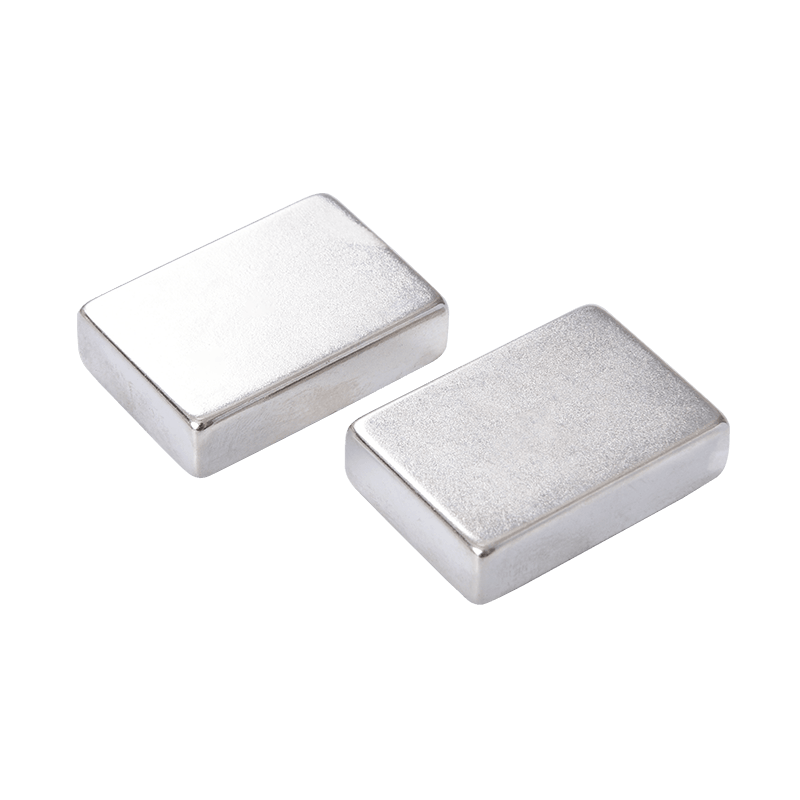

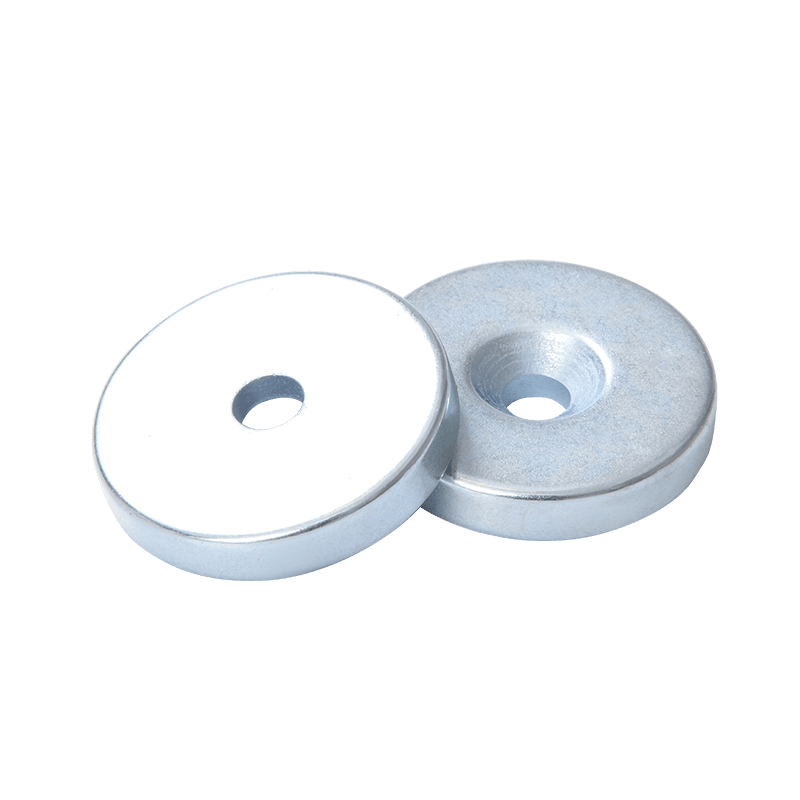

In modern technology and industrial fields, high-performance magnets are increasingly used. Among them, Special Shaped NdFeB Magnet (specially shaped NdFeB magnet) has become a key component in many industries with its unique magnetic properties and diverse shape designs. This article will delve into how to scientifically select material formulations to manufacture Special Shaped NdFeB Magnet with specific magnetic properties, and analyze its practical applications and advantages in different application fields.

When selecting the material formula of Special Shaped NdFeB Magnet, we need to comprehensively consider it based on scientific principles and practical application requirements. First of all, it is necessary to clarify the magnetic performance parameters of the required magnet, such as magnetic energy product (BHmax), coercive force (Hc), etc. These parameters will directly affect the performance of the magnet in specific applications.

Secondly, chemical composition is a key factor affecting magnetic properties. NdFeB magnets are mainly composed of neodymium (Nd), iron (Fe), boron (B) and other elements. Their content and proportion have a significant impact on the magnetic properties. Scientific research shows that by precisely controlling the content and proportions of these elements, the magnetic properties of magnets can be optimized. Therefore, when selecting material formulas, it is necessary to comprehensively consider the role of various elements and the balance between them.

In addition, adding elements is also an important means to optimize magnetic properties. By adding some trace elements, such as dysprosium (Dy), cobalt (Co), etc., the coercive force and thermal stability of the magnet can be further improved. The selection and amount of these added elements need to be determined based on specific application requirements to ensure the stability and reliability of the magnet in a specific environment.

Finally, the manufacturing process is also an important factor affecting the performance of magnets. During the manufacturing process, sintering temperature, time, pressure and other parameters need to be strictly controlled to ensure that the density and magnetic properties of the magnet are optimal. At the same time, the feasibility and stability of the manufacturing process also need to be considered to ensure consistent performance and quality of mass-produced magnets.

Special Shaped NdFeB Magnet has been widely used in many fields due to its magnetic properties and diverse shape designs.

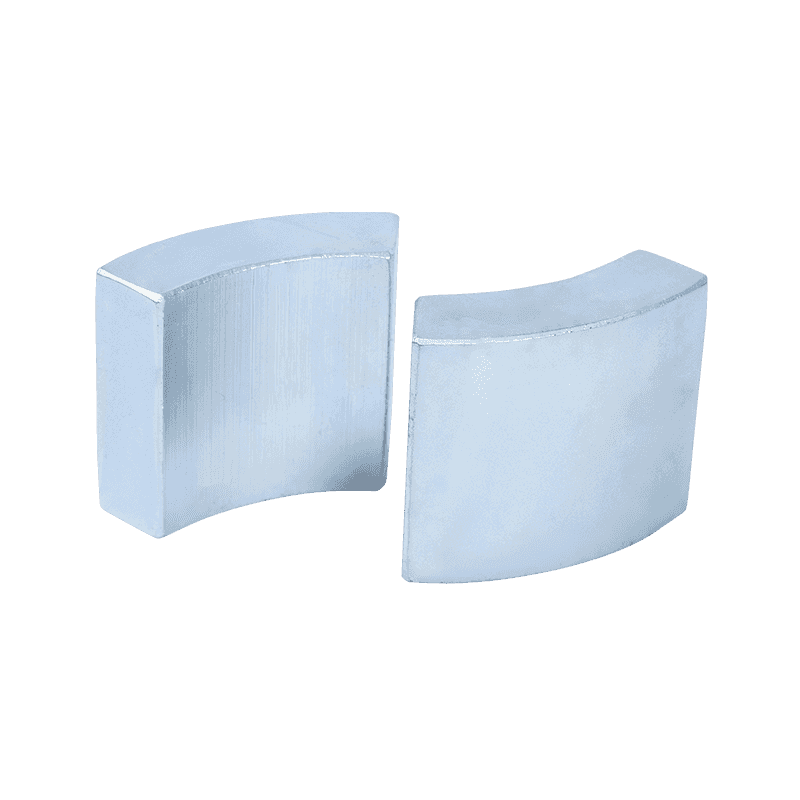

In the field of motors, Special Shaped NdFeB Magnet is an indispensable component. The magnets in the motor need to be customized according to the motor's design requirements to improve the motor's performance and efficiency. Special Shaped NdFeB Magnet can meet the needs of various complex shapes and sizes, ensuring efficient and stable operation of the motor. At the same time, due to its high magnetic energy product and coercive force, Special Shaped NdFeB Magnet can also effectively reduce the size and weight of the motor and improve the integration and performance of the entire system.

In the automotive field, Special Shaped NdFeB Magnet is also increasingly used. Whether it is the drive system of electric vehicles or the control system of traditional vehicles, high-performance magnets are required. Special Shaped NdFeB Magnet plays an important role in the automotive field due to its small size and high magnetic performance. For example, in the drive system of electric vehicles, Special Shaped NdFeB Magnet is used to drive motors to achieve efficient and stable power output; in automotive safety systems, magnets are also used in sensors and actuators to ensure vehicle safety. and stability.

In the field of consumer electronics, with the popularity of smart devices, the demand for magnets is also increasing. Special Shaped NdFeB Magnet is widely used in smart devices such as mobile phones, tablets, and headphones due to its small size and high magnetic performance. Whether it is used for functions such as automatic screen rotation, sound transmission or vibration feedback, Special Shaped NdFeB Magnet plays an important role.

In the field of medical equipment, Special Shaped NdFeB Magnet also plays an important role. For example, in magnetic resonance imaging (MRI) equipment, Special Shaped NdFeB Magnet is used to generate powerful magnetic fields to achieve high-resolution medical imaging. These devices have very strict requirements on the shape and magnetic properties of the magnets. Special Shaped NdFeB Magnet can meet these requirements and provide strong support for medical diagnosis and treatment.

Special Shaped NdFeB Magnet plays an important role in modern technology and industry with its magnetic properties and diverse shape designs. By scientifically selecting material formulas and manufacturing processes, Special Shaped NdFeB Magnets with specific magnetic properties can be manufactured to meet the needs of different application fields. With the continuous development of technology and the expansion of application fields, the application prospects of Special Shaped NdFeB Magnet will be broader.

English

English русский

русский Español

Español