Special Shaped NdFeB Magnet is the preferred solution in the following specific cases:

High precision requirements:

NdFeB magnets have high precision and tolerance can be controlled within ±0.02mm, which is critical for applications that require high-precision magnetic fields. For example, in equipment such as instrumentation, electroacoustic motors, magnetic separation and magnetization, where there are precise requirements for magnetic field distribution and intensity, Special Shaped NdFeB Magnet is the choice due to its high precision.

High magnetic energy product and coercive force requirements:

NdFeB magnets have extremely high magnetic energy product and coercive force, and can absorb objects equivalent to 640 times their own weight. In applications that require strong magnetic fields or high magnetic field stability, such as high-performance motors, precision measuring instruments, etc., Special Shaped NdFeB Magnet can provide enough magnetic force to meet the needs.

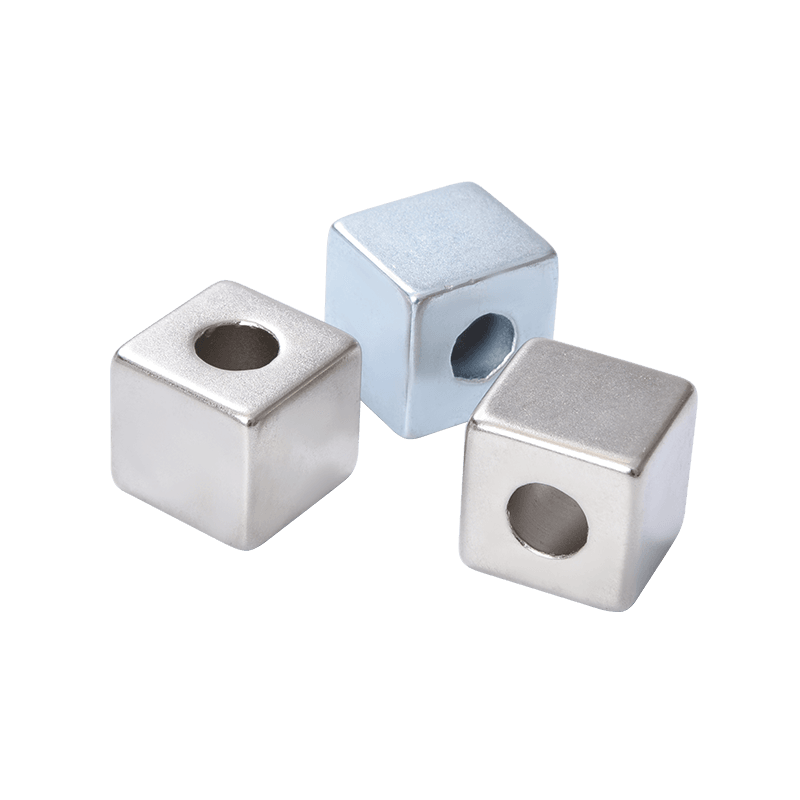

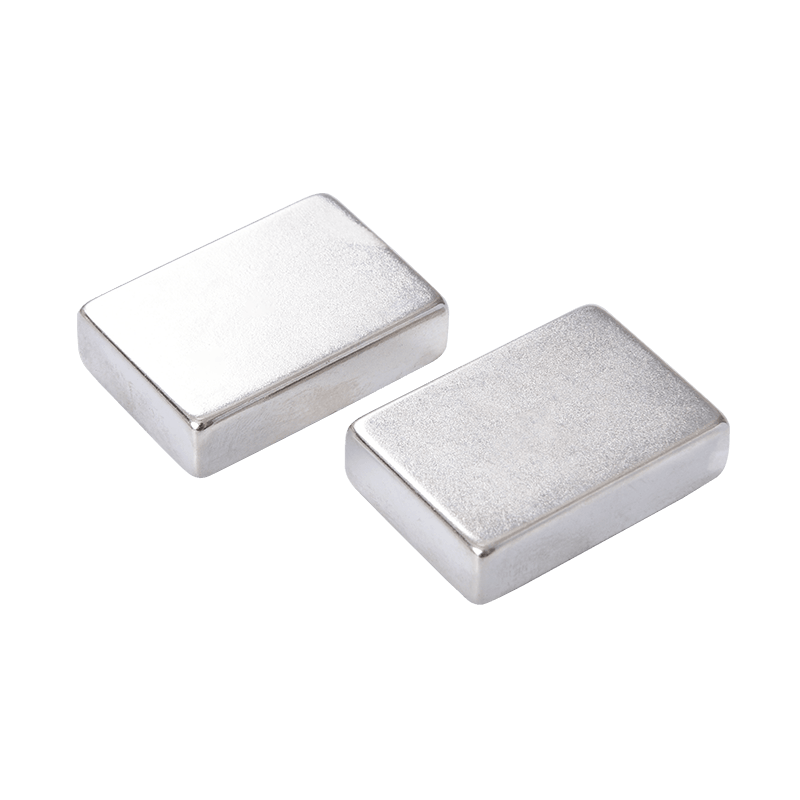

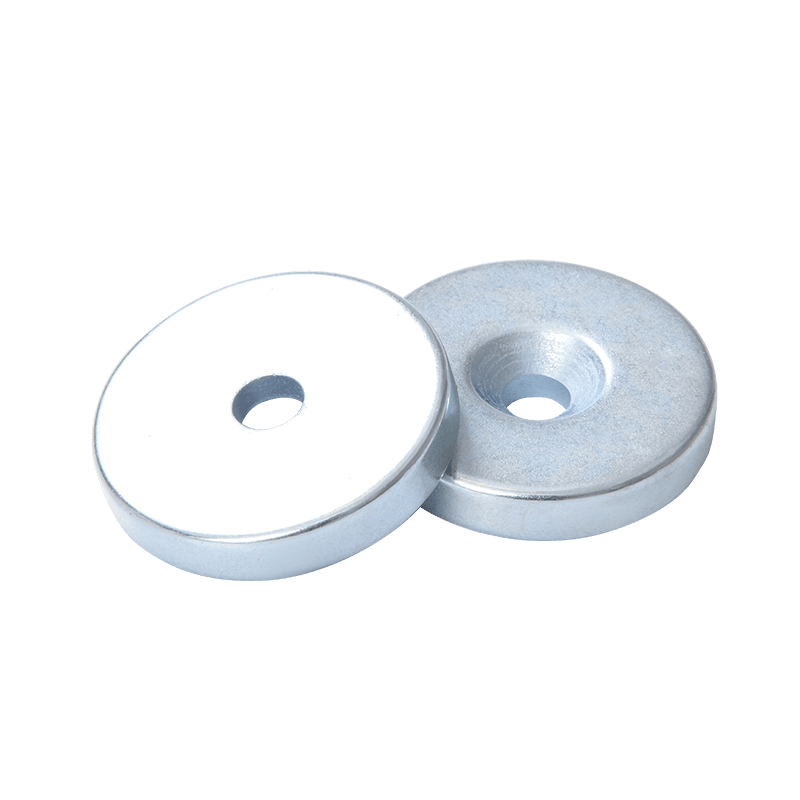

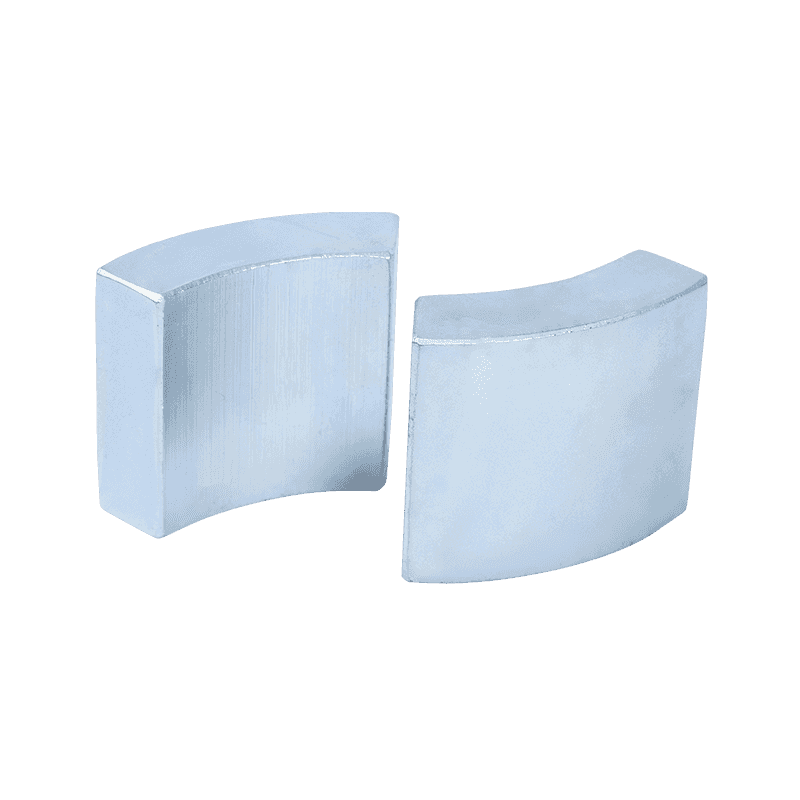

Special shape and size requirements:

NdFeB magnets have good mechanical properties and can be easily processed into various shapes, including special-shaped magnets. In applications that require magnets of special shapes or sizes, such as micro devices, automation equipment, complex mechanical structures, etc., Special Shaped NdFeB Magnet can provide customized solutions.

Cost-effectiveness:

NdFeB magnets have stable performance and good cost-effectiveness. Although its raw material cost may be relatively high, due to its high magnetic energy product and coercivity, the same magnetic field effect can be achieved in a smaller volume, thereby reducing the overall cost. Special Shaped NdFeB Magnet is a cost-effective solution in applications that require high performance and have certain requirements on cost.

High-temperature working environment:

NdFeB magnets have an operating temperature of up to 200°C and are suitable for applications in high-temperature environments. In fields such as motors, sensors, aerospace, etc. that need to withstand high temperatures, Special Shaped NdFeB Magnet can meet the requirements for high-temperature stability.

In summary, Special Shaped NdFeB Magnet is the preferred solution in specific situations such as high precision requirements, high magnetic energy product and coercivity requirements, special shape and size requirements, cost-effectiveness, and high-temperature working environments.

English

English русский

русский Español

Español