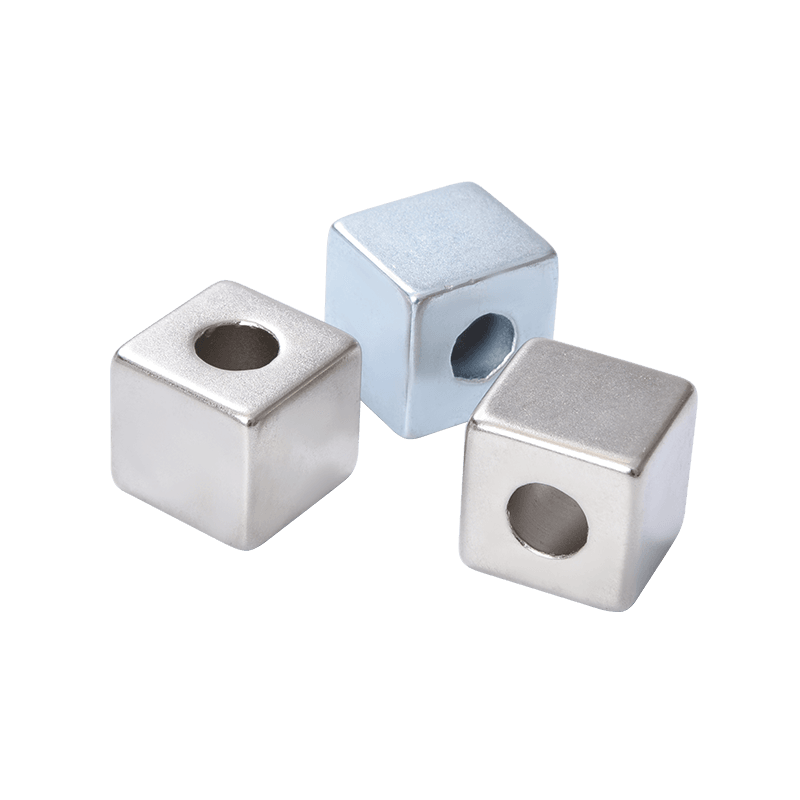

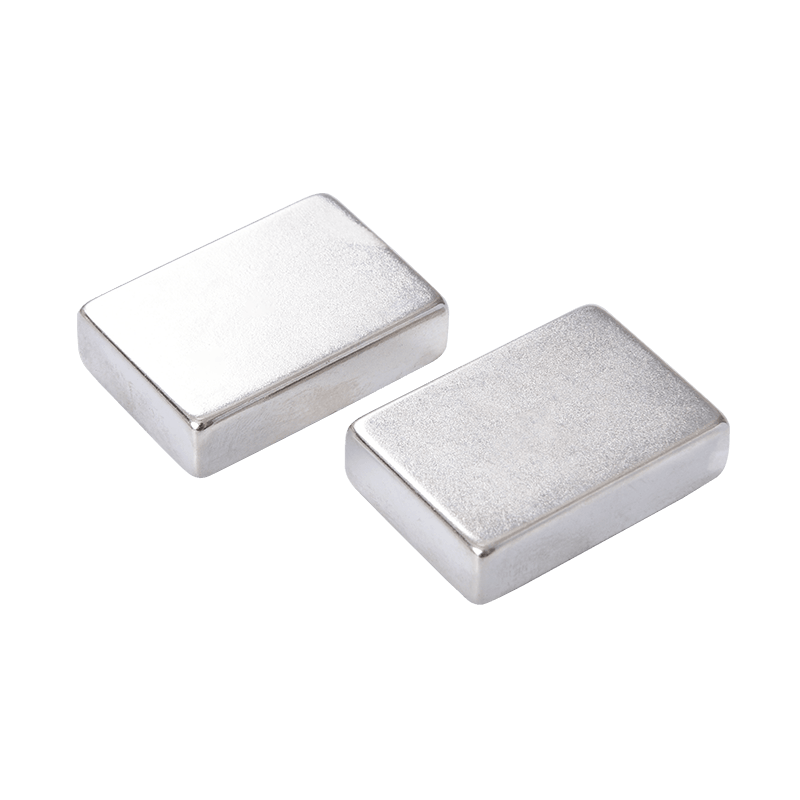

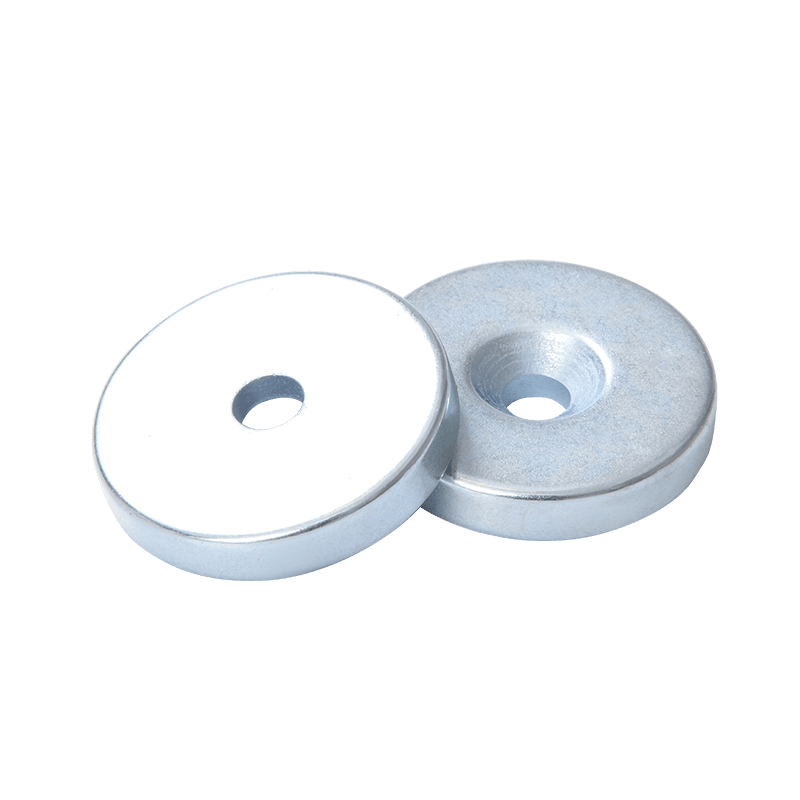

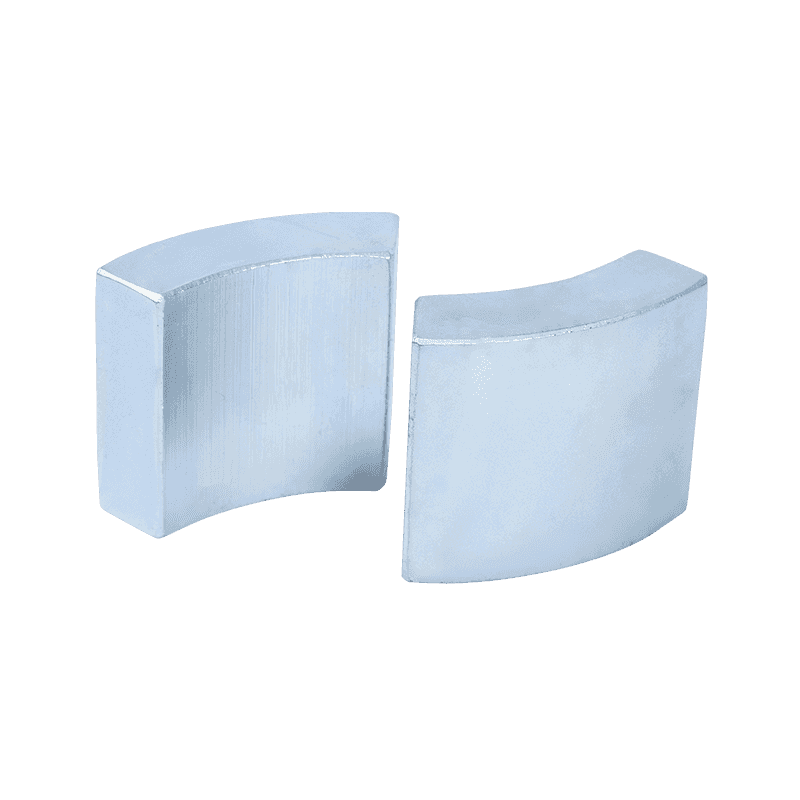

In today's rapid development of modern science and technology, Special Shaped NdFeB Magnet has become an indispensable key material in many industries with its excellent performance and wide application fields.

1. Design stage

The production of special-shaped NdFeB magnets starts with careful design. Our professional engineers will use advanced computer-aided design (CAD) software to draw precise magnet shapes and sizes according to the specific needs of customers. Whether it is complex geometric shapes or special dimensional requirements, we can accurately convert them into feasible design solutions. During the design process, engineers will also fully consider factors such as the magnetic field distribution, magnetic strength and use environment of the magnet to ensure that the final product can meet the various application needs of customers.

2. Raw material preparation

High-quality raw materials are the basis for the production of high-quality special-shaped NdFeB magnets. We select high-purity neodymium, iron, boron and other metal elements, and undergo strict screening and testing to ensure that they meet international standards. These raw materials will be mixed in a certain proportion and then sent to a vacuum melting furnace for melting. Under high temperature and high pressure, the metal elements are fully fused to form a uniform alloy melt.

3. Powder making process

The smelted alloy melt needs to go through the powder making process to convert it into fine powder particles. We use advanced airflow grinding technology to spray the alloy melt into high-speed airflow, so that it is instantly broken into fine powder. The size of these powder particles is usually between a few microns and tens of microns, with good fluidity and dispersibility. During the powder making process, we will also strictly control and test the powder to ensure that it meets production requirements.

4. Molding process

Next is the molding process, which is the key step in determining the shape of the special-shaped magnet. We use advanced powder metallurgy technology to load the powder particles into a specific mold, and then press them under high pressure to form them into the desired shape. For some complex special-shaped magnets, we will also use special molding processes such as injection molding and extrusion molding to ensure the accuracy and quality of the product. The magnet blank after molding needs to be further processed and treated to remove burrs and impurities on the surface and improve the appearance quality of the product.

5. Sintering process

The magnet blank after molding needs to be sintered to increase its density and magnetic strength. We put the magnet blank into a high-temperature sintering furnace and sinter it under certain temperature and atmosphere conditions. During the sintering process, the powder particles diffuse and fuse to form a dense crystal structure. After sintering, the magnetic strength and stability of the magnet will be significantly improved.

6. Post-processing process

The sintered magnet also needs a series of post-processing processes to meet different application requirements. For example, we can perform surface treatment on the magnet, such as electroplating, spraying, etc., to improve its corrosion resistance and wear resistance; we can also magnetize the magnet to give it a specific magnetic field direction and magnetic strength. In addition, we will also conduct strict quality inspections on the magnet, including dimensional accuracy, magnetic strength, surface quality and other aspects, to ensure that every product meets the quality standards.

7. Finished product packaging

The special-shaped NdFeB magnets that have passed strict inspection will be carefully packaged to ensure that they are not damaged during transportation and storage. We will use appropriate packaging materials and methods according to customer requirements, such as carton packaging, foam packaging, wooden box packaging, etc. At the same time, we will also mark the product specifications, models, quantities and other information on the packaging for customers to identify and use.

The production process of Special Shaped NdFeB Magnet is a complex and delicate process that requires strict control and testing at multiple links. With advanced production equipment, professional technical team and strict quality management system, our company is committed to providing customers with high-quality special-shaped NdFeB magnet products. No matter how special and complex your needs are, we can provide you with satisfactory solutions. Choosing us means choosing quality and peace of mind!

English

English русский

русский Español

Español