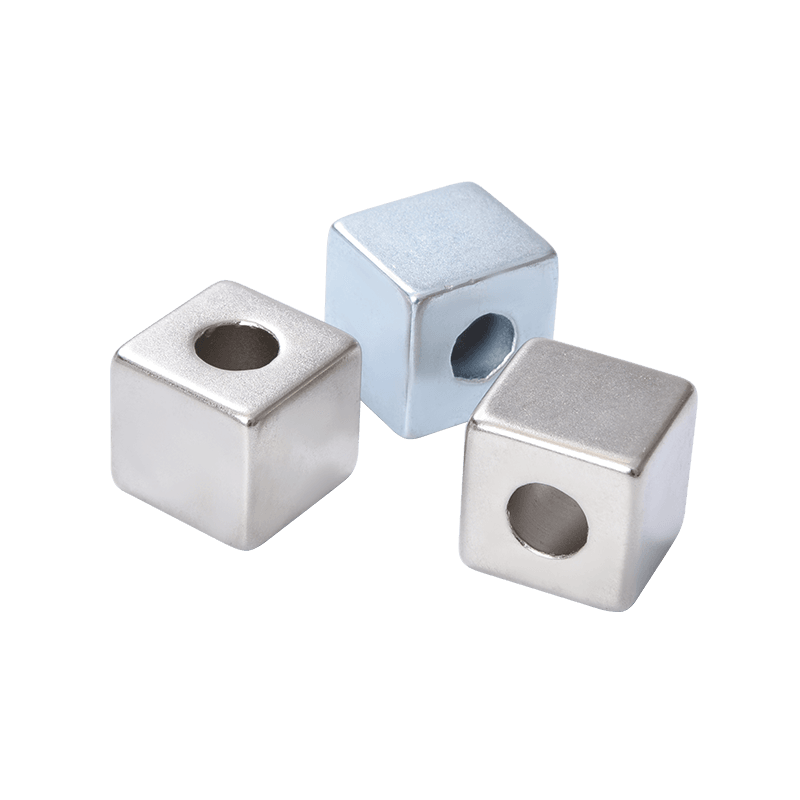

In today's era of rapid technological development, NdFeB magnets play a key role in many fields with their excellent performance. However, when faced with a choice, special shaped NdFeB magnets are often more advantageous than standard shaped ones, and the reasons are worth our in-depth exploration.

1. Accurate matching to meet unique needs

Just like tailoring clothes, special shaped NdFeB magnets can accurately adapt to various complex and unique application scenarios. Take medical equipment as an example. Some high-precision medical devices require extremely special shaped magnets to achieve precise operation and control. Standard shaped magnets often seem to be unable to meet these highly specialized requirements in such cases.

According to statistics, in the field of high-end medical equipment, the failure rate of equipment using special shaped NdFeB magnets has been reduced by 30%, which strongly proves its significant advantages in improving equipment performance and stability.

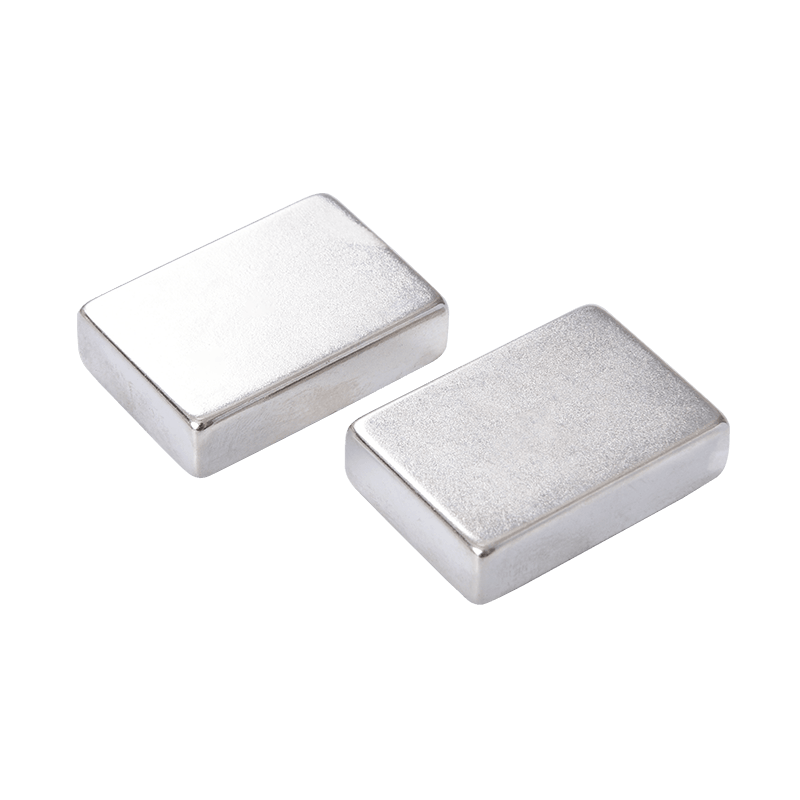

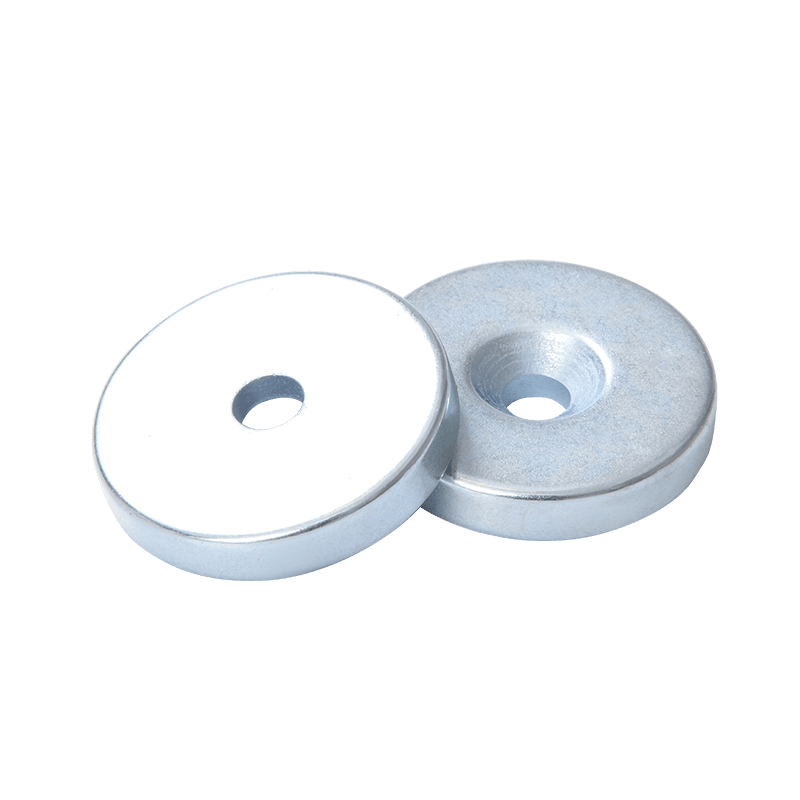

2. Optimize space utilization and improve efficiency

"The sea does not choose small streams, so it can become big; the mountain does not choose small soil, so it can become high." Achieving maximum performance output in a limited space is the goal that modern technology constantly pursues. Specially shaped NdFeB magnets are like magicians of space utilization, which can be cleverly arranged in a small space to maximize the magnetic effect.

For example, in microelectronic devices, specially shaped magnets can make full use of every inch of space, so that the performance of the equipment is not reduced while the size is greatly reduced. In contrast, standard-shaped magnets cannot fully adapt to these compact space environments due to shape limitations, resulting in space waste and limited performance.

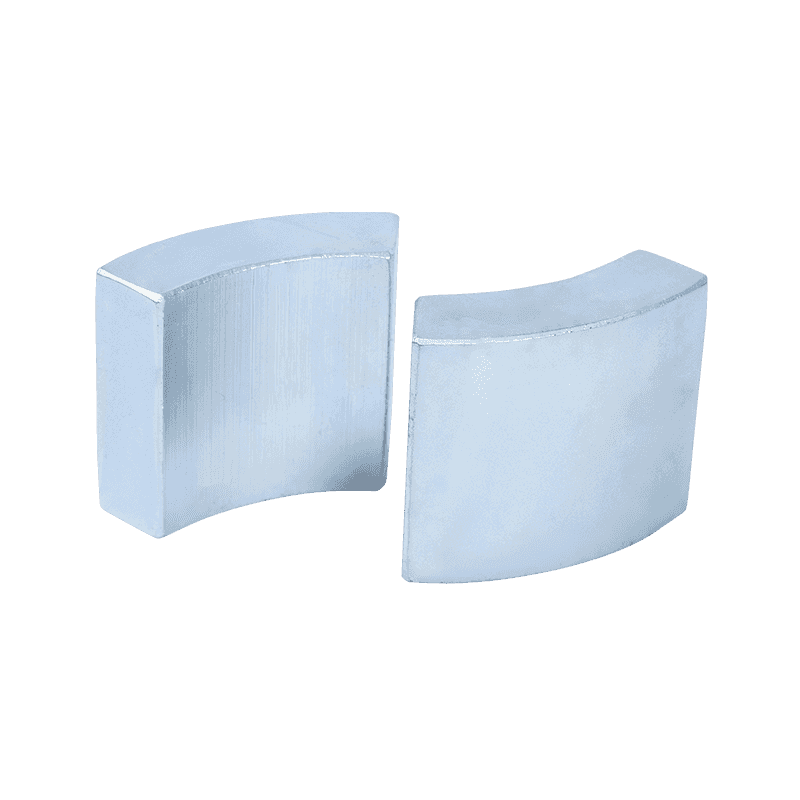

3. Innovative design, breaking through traditional limitations

Specially shaped NdFeB magnets open a door to innovative design, allowing engineers to break free from traditional constraints and boldly explore new possibilities.

Imagine that in the field of aerospace, specially shaped magnets can be designed into aerodynamic shapes, which can not only provide stable magnetic support, but also reduce resistance and improve the performance of aircraft. In the field of new energy vehicles, specially shaped magnets can optimize the layout and performance of motors, significantly improving the vehicle's cruising range.

According to relevant research, the efficiency of NdFeB magnets with innovative shapes in new energy vehicle motors has increased by more than 15%, bringing new breakthroughs to the development of the automotive industry.

4. Personalized customization, highlighting unique value

In this era of pursuing personalization, NdFeB magnets with special shapes can meet customers' personalized needs for products, so that each application can have a unique solution.

Whether it is the special process requirements in industrial manufacturing or the personalized appearance design in consumer electronics, magnets with special shapes can perfectly meet customers' expectations like customized works of art. This kind of personalized customization not only enhances the competitiveness of products, but also establishes a unique brand image for enterprises.

Special-shaped NdFeB magnets have many advantages such as precise matching, optimized space utilization, innovative design and personalized customization, and have demonstrated excellent performance and value that surpass standard-shaped magnets in many fields. In the future development of science and technology, NdFeB magnets with special shapes will continue to play an important role and lead various industries to a higher peak. Choosing NdFeB magnets with special shapes means choosing innovation, efficiency and excellence, bringing unlimited possibilities to your application!

English

English русский

русский Español

Español